Supply chain variability and the benefits of an AI-driven supply chain software

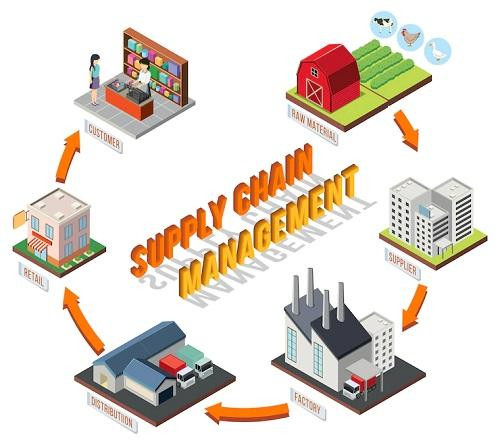

Most businesses today are expected to provide same-day shipping to not only meet escalated demand for goods but also fulfill customer’s expectations of faster delivery. As end-of-year projections will startle businesses with high demands, an efficient Supply Chain Planning Software system to fulfill it is needed. A salient supply chain management system takes stock of the different variables across the supply chain to mitigate any uncertainty while catering to the fluctuating demand. In 2021, the retail sector experienced drastic global inventory distortion. The estimated value for out-of-stock items was $1.14 trillion, with only half as much value in overstock items. The high degree of potential losses in these projections makes it crucial to mitigate variability and enhance predictability within the supply chain. Advanced buffer management tools are the need of the hour while heading into a hybrid work-world with temperamental variability.

Supply chain variability can arise due to a variety of factors such as natural disasters, epidemics, and geopolitical shifts. However, most of the variability generated by these factors can be eliminated by addressing specific supply planning solutions, management, and demand at regular intervals, through focused solutions.

- Supply Variability: Supply variability can occur at the procurement level as well as in-store inventory levels. When demands for goods escalate, insufficient resources for procuring components can lead to unmet consumer demand. Parallelly, if the demand slows down, excess inventory can take up expensive storage space in both warehouses as well as stores.

- Managerial Variability: Managerial variability surfaces due to inefficient management personnel and/or processes. To ensure reduced variability, it is important to optimize supply chain management for enhanced visibility. High degrees of visibility and development of holistic systems ensure that chances of delay in demand fulfillment are reduced and that the supply chain is optimized for risk-reduction.

- Demand-driven Variability: Demand-driven variability impacts every level of the supply chain. From warehouse inventory to transport and shipping, demand is the key driver while determining supply chain operations. Demand-driven variability arises due to global disruptions, seasonal events, and regional factors. However, demand-driven variability can be greatly reduced by demand sensing tools that enable risk reduction.

ThroughPut’s AI Software Suite facilitates advanced buffer management with Artificial Intelligence generating insights from base inputs. ThroughPut’s tool helps to achieve efficiency and transparency by eliminating bottlenecks in the best Supply Chain Planning Software. With a sound AI-driven S&OP process, risks can be significantly reduced with accurate demand sensing, inventory management, and warehouse optimization.

Comments

Post a Comment